1. Product description

Forged steel gate valve is a rigid solid gate, the direction of the gate and the direction of the fluid vertical, can be fully open or fully closed, the body is the integral forging, very suitable for high temperature and high pressure working conditions. Gate valve fluid resistance is small, sealing surface by medium erosion and erosion is small, the standard valve opening and closing more effort, medium flow direction is not limited, no turbulence, no pressure reduction, simple form, short structure length, good manufacturing technology, wide range of application.

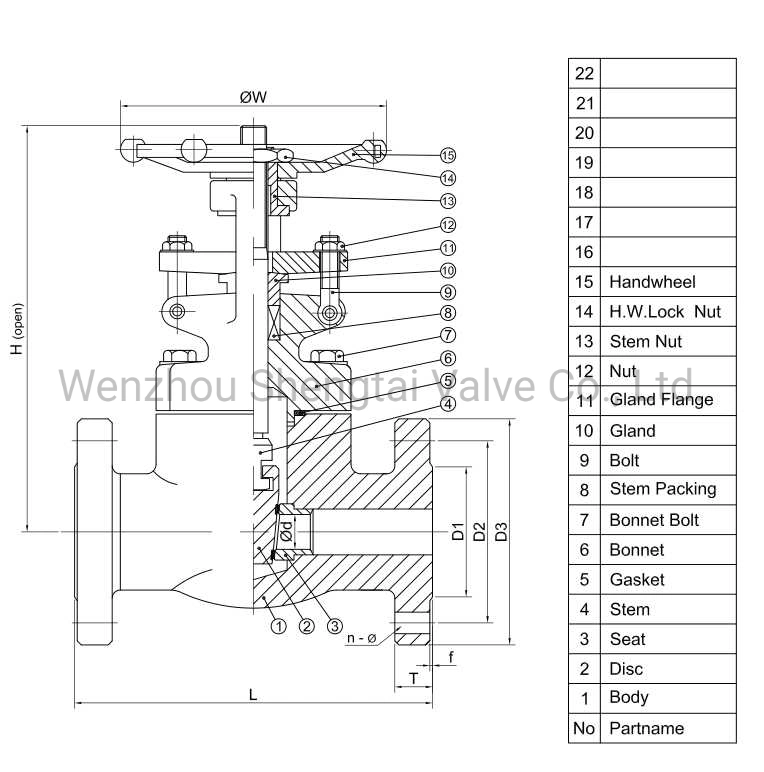

2. Forged steel gate valve main parameters:

| Standard: | API, JB, GB, ANSI | shape: | medium |

| Connection form: | lange connection flow | direction: | bidirectional |

| Applicable medium: | water, steam, oil, etc | Specification: | dn10-dn50 |

| Stem screw position: | rising stem gate valve | purpose: | fluid switch |

| Driving mode: | manual | model: | Z41H/Z41W, etc |

| Main material: | carbon steel, stainless steel, aluminum alloy steel, etc. | Pressure classes: | 150LB~2500LB (0.6-42.0mpa) |

Size: DN10 - DN50

Pressure class :150LB-2500LB (0.6-42.0mpa)

Valve body material :A105, F11, LF2, F304, F316, etc

Applicable medium: water, steam, oil, etc

Connection: flange, socket welding, NPT internal thread

Operation mode: manual

3.Applicable Temperature range:

(1), Carbon steel, available temperature range: -29ºC~+425ºC

(2), Alloy steel, available temperature range: ≤550ºC

(3), Stainless steel, available temperature range: -196ºC~+ 200ºC

4. Forged steel gate valve features:

(1), Full size or reduced size design

(2), Three bonnet types: bolted, welded, self-sealing

(3), sealing surface is not easy to wear, abrasion, good sealing performance, long life.

(4), compact structure, good opening and closing, small height, convenient maintenance.

(5), Inverted sealing of the body

(6), Simple in shape, short face-to-face length, good technic in producing, and widely applied

5. Working principle of forged steel gate valve:

(1)The oDTurator of the gate valve should be disc, the movement direction of the disc should be vertical to the direction of the service flow, the gate valve is served only for full-open and full close, can't be applied for adjust the flow or throttle function.The disc have two sealing surface, the most commonly used gate valves should be wedge gate valve, its sealing surface form Wedge angle, the wedge angle can be changed with valve parameter, the disc of wedge gate valve can be integral, it's called as solid wedge disc; The disc can also be made with reforming a little in shape, improve the technic, to compensate the deviation of sealing surface angle durging the machining process, it's called as flexible disc.

(2), When the gate valve closed, the service pressure make the tightness of the sealing surface, say the pressure service press the disc to other sealing surface of the seat, then the tightness will be realized, it's called Self-tightness. Most of the gate valve are forced-sealing type, say to ensure the tightness under closed position, outside force should be imposed to the disc, press the disc to the seat in the direction vertical to the service.

(3), When the gate valve opened, the rising height of the disc should be the same as valve bore diameter, the bore of flow should be completely smooth, but this position can't be scouted under running. In practice, the top of the stem can be a symbol of full-open position when the stem can't be further rised. To avoid the block phenomena arise from temperature change, generally, after the gate valve is opened to the top, we'll turn back 1/2-2 cycle of handwheel, then we take such position as the full-open position. So the full-open position of gate valve depend on the disc's position(disc' travel)

You need to consult more detailed product information

Please consult me