Product Description

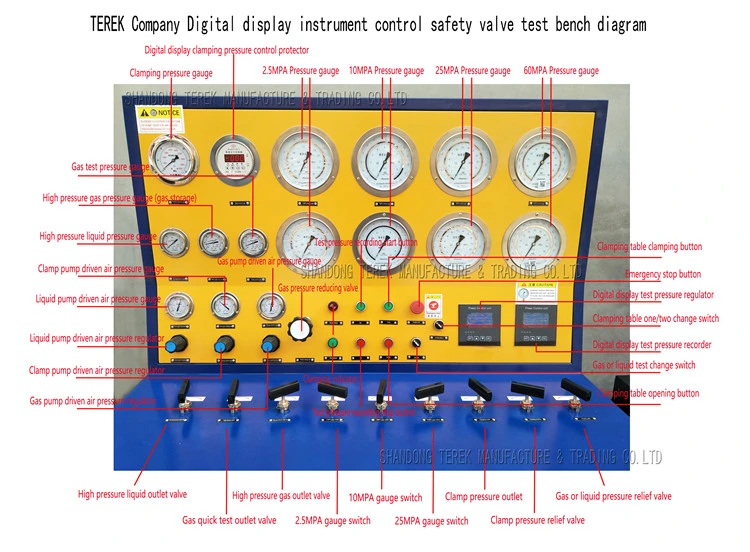

Used for testing all kinds of safety valve, such as spring directly load safety valve, Power assisted safety valve, Supplementary loaded safety valve, fully open, slightly open, flange, thread type safety valve. Safety valve test bench is to use high pressure air or nitrogen as the medium to test the sealing performance of the safety valve, jump pressure, back seat pressure, etc., for a variety of safety valve set pressure adjustment, set pressure test, discharge pressure test, back seat pressure test, test the pressure sealing performance of the safety valve, leakage rate. Safety Relief Valve Test bench has obvious advantages in techniques, test accuracy, safety etc.

1. Automatic hydraulic clamping, Adjustable clamping force, equipped with gauges displaying corresponding clamping forces, The material of the clamping valve fittings is stainless steel.

2.The same valve size, TEREK products can test bigger pressure; The same pressure, TEREK products can test bigger valve size; Provide quicker and more accurate clamping force. Control panel with different gauges for reference .

3. With Our self Products air driven booster pump , build up pressure quickly and Holding pressure constant; With high pressure stainless needle valve, installed in either direction, high pressure resistant, high durability;

4.Normally we use double stage air driven high pressure gas booster pump and High pressure air driven liquid pump for building into the safety valve test bench.

We are able to provide our customers better technical support, price and service.

5. Test various relief valves such as full-open, micro-open, metric, flanged and threaded etc. Safety valve test bench is used for various safety valve setting pressure adjustment, the whole set pressure detection, discharge pressure detection, back seat pressure testing, assessment of its pressure safety performance etc.. , Safety Relief Valve Test bench has obvious advantages in techniques, test accuracy, safety etc.

Product parameters

Safety valve test bench is used for various safety valve setting pressure adjustment, the whole set pressure detection, discharge pressure detection, back seat pressure testing, assessment of its pressure safety performance etc

Main technical data for Manual/ Computer control safety valve test bench

| Product name | Intelligent digital display instrument control system safety valve test bench |

| Model | TVT-40-DN400-MC |

| Drive air source pressure | 3-8bar. |

| Outlet pressure Control unit | Drive air regulator valve |

| Power source | TEREK gas booster pump |

| Gas pump pressure ratio | 60:1 |

| Test medium | Normal air/Nitrogen |

| Pressure testing range | 0-480bar for option |

| When the driven air pressure is 6.6bar | Gas High pressure outlet pressure is 400bar. |

| Min gas inlet pressure | 25 bar |

| Max gas inlet pressure | 480 bar |

| Power source | TEREK liquid booster pump |

| Liquid pump pressure ratio | 64:1 |

| Test medium | Water |

| Pressure testing range | 0-480 bar for option |

| When the driven air pressure is 6.3bar | Liquid High pressure outlet pressure is 400bar. |

| Test valve diameter | DN20-DN400 (0.8inch-15.7inch) |

| Pressure control accuracy | less than 1%F.S; |

| Pressure measurement accuracy | 0.4 pressure gauge |

| Valves and piping | High pressure needle valve and stainless steel piping |

| Pressure range scale | 0-2.5MPA ,0-10MPA ,0-25MPA ,0-60MPA (Can be customized) |

| Interface type | Screw and flange type |

| Clamping way | Hydraulic cylinder clamping force |

| Clamping pump | Hydraulic pump LKD-40 |

| Clamping force range | 30Tons |

| Control and testing | Intelligent digital display control, can be pre - set clamping pressure and test pressure. |

| Supply voltage | 50Hz -60Hz ,220V |

| Control console Weight | 400 KG |

| Control console Size | 1320*920*1550mm |

| Control console Packing size | 1440*1000*1690mm |

| Clamping table weight | 700 KG |

| Clamping table Size | 1370*820*830mm |

| Clamping table Packing size | 1500*900*990mm |

| Packing type | Standard export wooden case |

| Production time | 20-25 days. |

| Delivery way | Sea transportation |

| Provide operation instruction, operation video, U disk backup, repair kit, seal fitting, screw fitting, Seal ring, PU pipe etc | |

Detailed Images

System configuration

The safety valve test bench system is mainly composed of power system, valve clamping system, testing system, electrical control system.

1)Power system Air drive gas or nitrogen booster pump, air driving pressure 3-8bar;Maximum Output pressure 480bar; Provide high pressure for valve test.

2)Clamping system. The liquid booster pump provides high pressure power. Cylinder clamping ensures the sealing between the tested parts and the pipeline.

3)Test system. Pressure range: 0-1MPA; 0-2.5 MPA, 0 -16 MPA, 0-25 MPA and 0-60MPA. The performance index is up to the accuracy of ± 1%FS, and the range ratio is 100:1.

4) Electrical control system. Reliable and high quality electrical components ensure high efficiency of the testing process.

Application Fields

The safety valve checkout platform is a device that simulates the working environment of the safety valve offline and makes the internal pressure rise to the safety valve lift. At the same time, the pressure gauge on the device can show the starting pressure of the safety valve. The test pressure can be checked to check the starting pressure (also called opening pressure, setting pressure) of the safety valve.

Suitable for performance testing of fixed pressure, backseat pressure and tightness of direct loading and pilot safety valves.

Packaging & Shipping

Company Information

TEREK Company focus on provide various kinds of pneumatic and hydraulic booster pumps, booster systems, High pressure filling equipment, pressure testing system and fluid pressure solutions to the customers all over the world etc. With more than 18 years experiences in fluid pressure exchange and controlling field.

Our main products including:

High Pressure Booster Pumps (Air Driven Gas Booster Pump, Air Driven Liquid Pump, Air Amplifiers)

High Pressure Systems (Gas/Liquid Booster Stations,FM200 filling machine, Tube Expanding Machine)

High Pressure Test Equipment(Hydraulic Pressure Test Machine, Burst/Hydrostatic test machine, Safety Valve Test Bench, Impulse Testing Machine, etc.)

1. We'd like to provide our professional advice regarding machines, materials, packing and market for this product.

2. We'd like to customize special machine according to customer's request.

3. We'd like to help our customers for booking ship as customer request.

5. Operation manual will be provided after shipment.

6. We provide two year warranty.

7. Free wearing parts will be sent together with the machine .

1.Q : Are you manufacturer ?

A: Yes, We are the manufacturer with continuous and improved R&D. Production, Quality Check and service supply.

2.Q : Can I get your price list ?

A: Yes, Sure. In order to send you our available offered price. Please choose the products and let us know the product model and requirement in detail.

3.Q : Do you have stock for all items?

A:In general, we have some stock, while if you need a bulk order, we still need time to produce it. Of course, we will inform all details you before your payment.

4.Q : What is payment terms ?

A: Sample order : 100% full payment before start to production;

Large order : 30% deposit first, 70% pay after see the BL copy ;